wastewater treatment in three phases

The oxyfix® is a solution for the treatment of wastewater with a small footprint. Three phases take place in turn to complete the treatment and discharge the treated water.

first step : primary settling

The oxyfix® micro-station consists of three chambers. The first compartment separates the suspended matter in the wastewater. Heavier matter slowly sinks to the bottom of the compartment and lighter matter rises to the surface. This slow process is called decantation. It provides pre-treatment before the second oxyfix® compartment. Thanks to its 3 m³ decanter, the oxyfix® micro-station provides one of the largest decantation volumes of individual treatment systems. The removal frequency of the sludge generated by this step is estimated at 48 months, one of the lowest on the market.

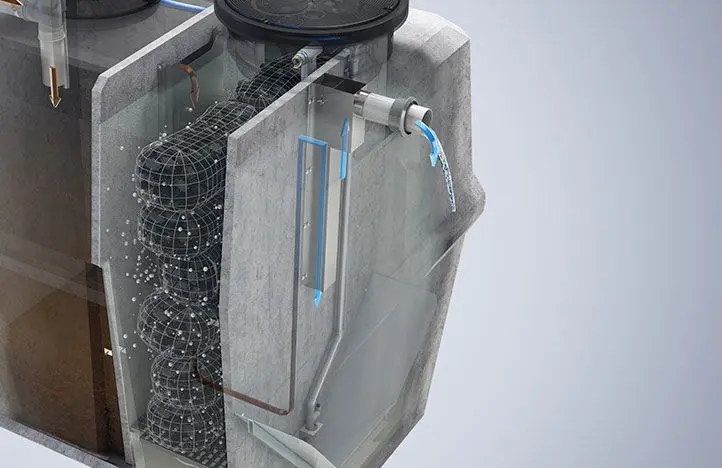

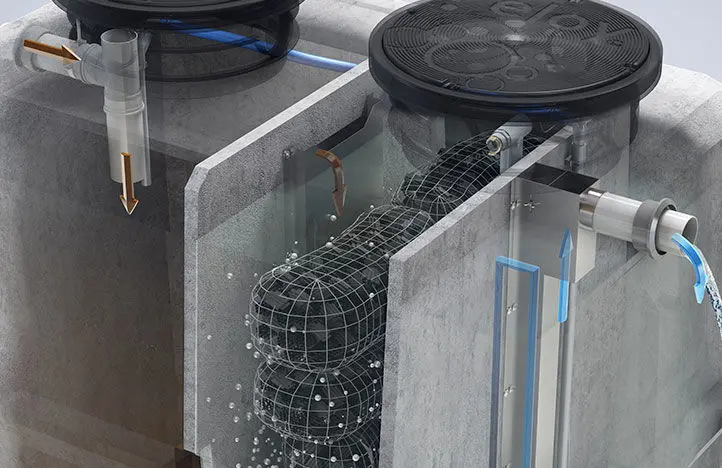

second step: reaction

The second compartment of the oxyfix® micro-station is the called the bioreactor. This is where the bulk of the treatment work takes place. Oxygen is injected into the reactor with a compressor (located in a cellar or laundry room) via diffusers which create small bubbles. The oxygen promotes the growth of bacteria which fasten themselves to an unalterable, clog-free medium: the oxybee®. Once the oxybees® have been colonised by the bacteria, the latter start to digest the polluting matter and treat the water.

third step: clarification

The last round of this intense battle takes place in the third and last compartment of the oxyfix®. After making its way through the two first compartments, the treated water will still contain small quantities of residual particles and sludge. Additional decantation will cause the small amounts of suspended particles to sink to the bottom of a funnel to be redirected back to the first compartment. The treated water is discharged in the environment or distributed by an irrigation system.